E-PAC®

Component fixation through positive locking

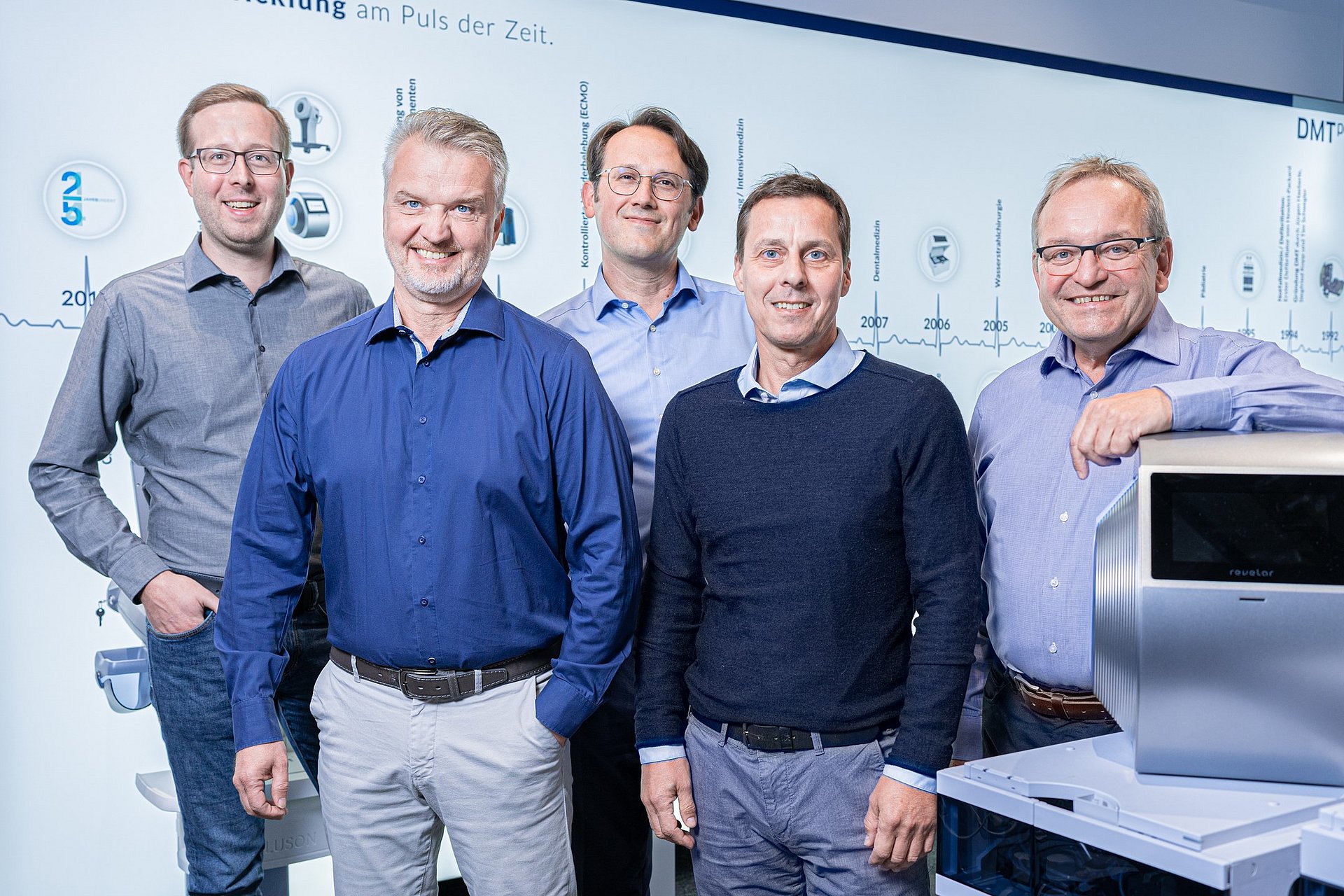

Innovation led to the founding of DMTpe

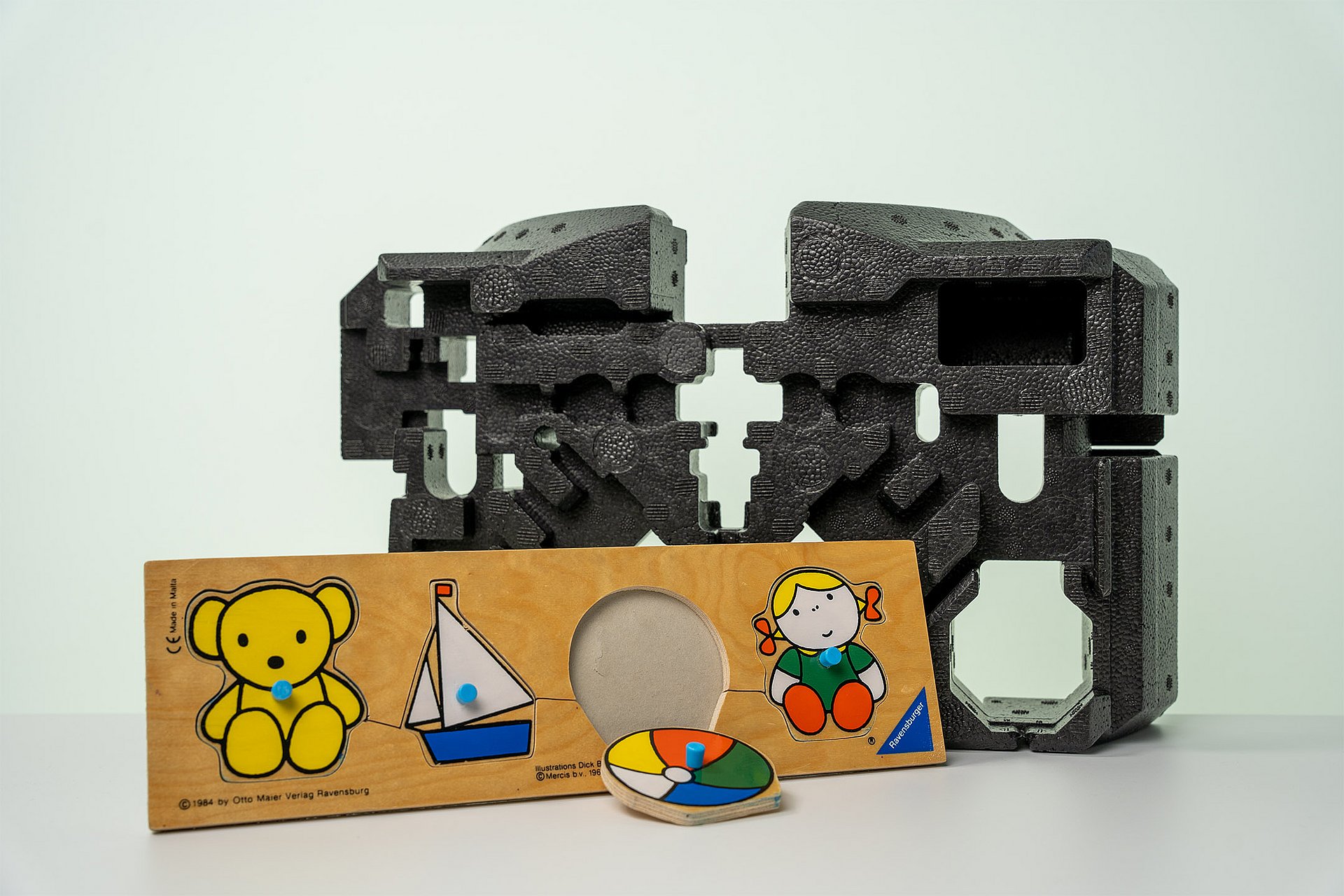

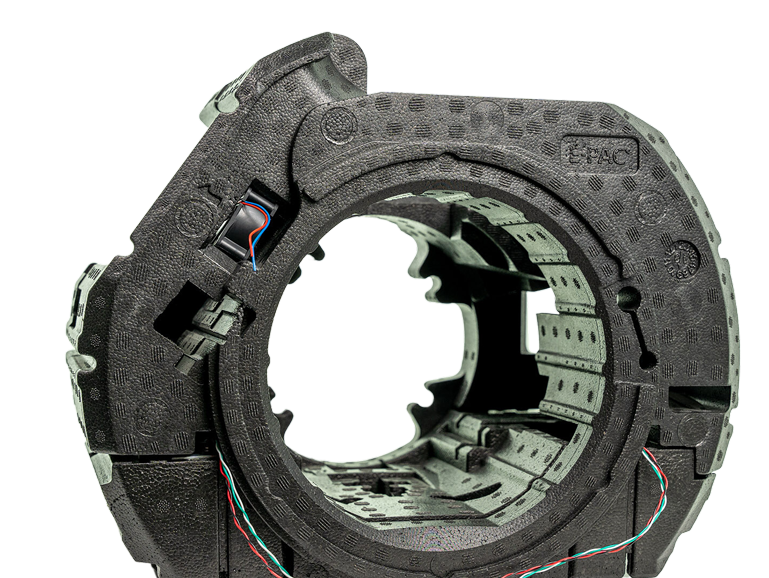

The E-PAC® system is part of a unique DMTpe success story. This is a housing construction made of expanded polypropylene (EPP) foam, which embeds all the components of an appliance in a form-fit using a predefined plug-in principle. The advantages are manifold: from the reduction of components, simplified assembly and disassembly to overall lower product development costs. In addition to the straightforward creation of prototypes and the simpler realization of the industrial design, synergy effects arise in the form of improved service characteristics. This makes the E-PAC® system a competitive alternative to conventional enclosure design.

E-PAC® - An innovation from DMTpe

As can be seen from the example shown, the material used for E-PAC® is a foamed plastic. Beads made from polypropylene granulate are expanded with steam, resulting in the very lightweight plastic EPP. A housing construction can then be milled from this plastic to fix the components in the correct shape,optimally route the cables and improve the thermal properties. Our customers also benefit from quick and easy assembly and disassembly.

Advantages of E-PAC

Targeted improvements to the device properties

- Improved thermal insulation

- Defined cable routing and cable routing without additional fastening elements

- Easy compliance with product return regulations thanks to the environmentally friendly concept

- Component and assembly fixing through positive locking

Significant reduction in product development costs due to

- Reduction of components

- Reduction in assembly time

Faster time to market

- Faster time to market thanks to reduced product development times