Prototyping

Everything from a single source - DMTpe

Prototypes are needed in every phase of product engineering. Be it to visualize the design, to make the shape and size comprehensible, to show initial functions, to create a fully functional initial sample or a small series. Prototypes offer us the opportunity to test the functionality and design with regard to your requirements in the initial phases of the development process. This enables us to identify challenges at an early stage and develop solutions more quickly.

Creative. Efficient. Cost-effective.

Rapid Prototyping - Proof-of-Concept

At DMTpe, we create prototypes as early as possible during the concept phase in order to simulate application and load situations. This is always done with the aid of state-of-the-art simulation software. This means that results can be tested and visualized quickly. This promotes an efficient development process and allows us to make well-founded joint design decisions. In addition, improvements to the digital models can be made quickly and cost-effectively even before we produce your first hardware prototype using manual or generative processes.

An important aspect in the creation of prototypes is the proof-of-concept. We want to be sure that the concepts and results developed are feasible and meet the previously defined requirements. This enables us to guarantee the feasibility and functionality of your prototype . Only after successful testing of the concepts and your approval will further resources be used to drive forward the actual product development. This allows us to save you time, costs and specialist resources and deploy them in a more targeted manner.

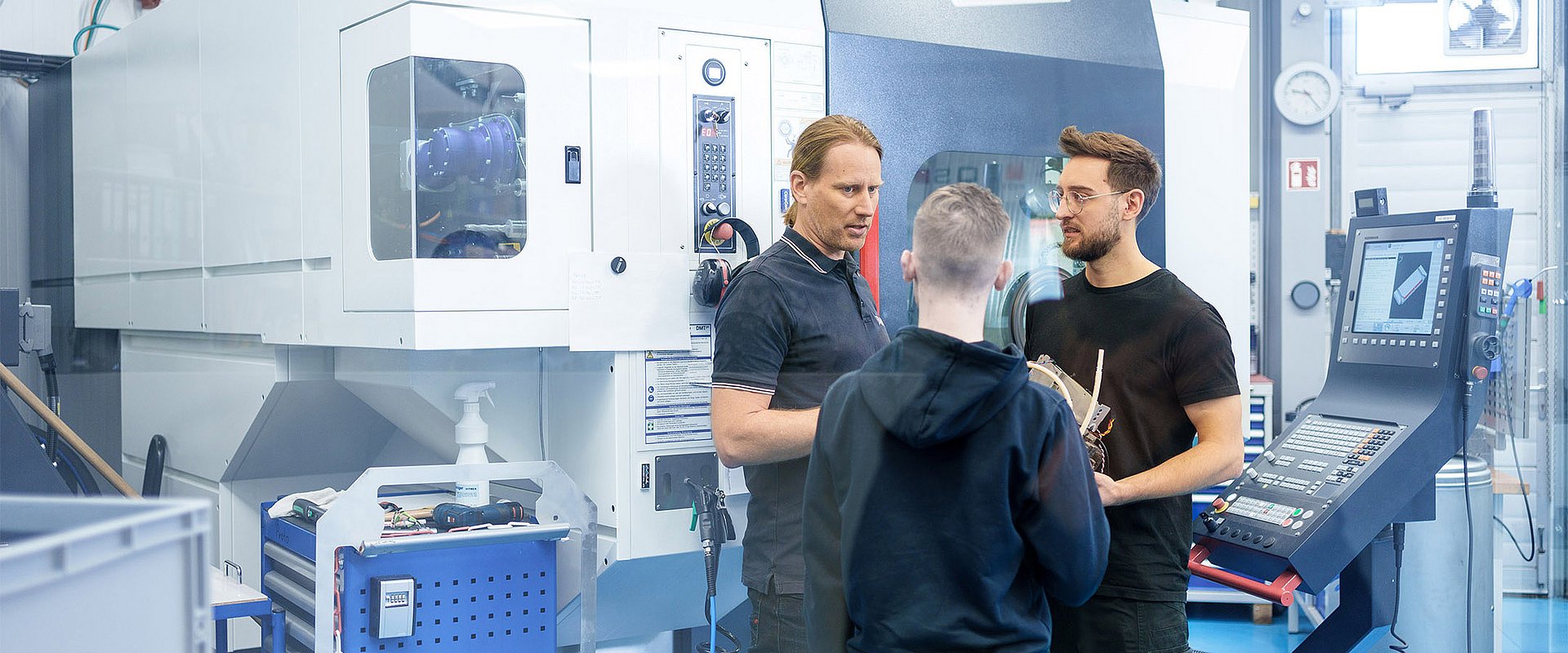

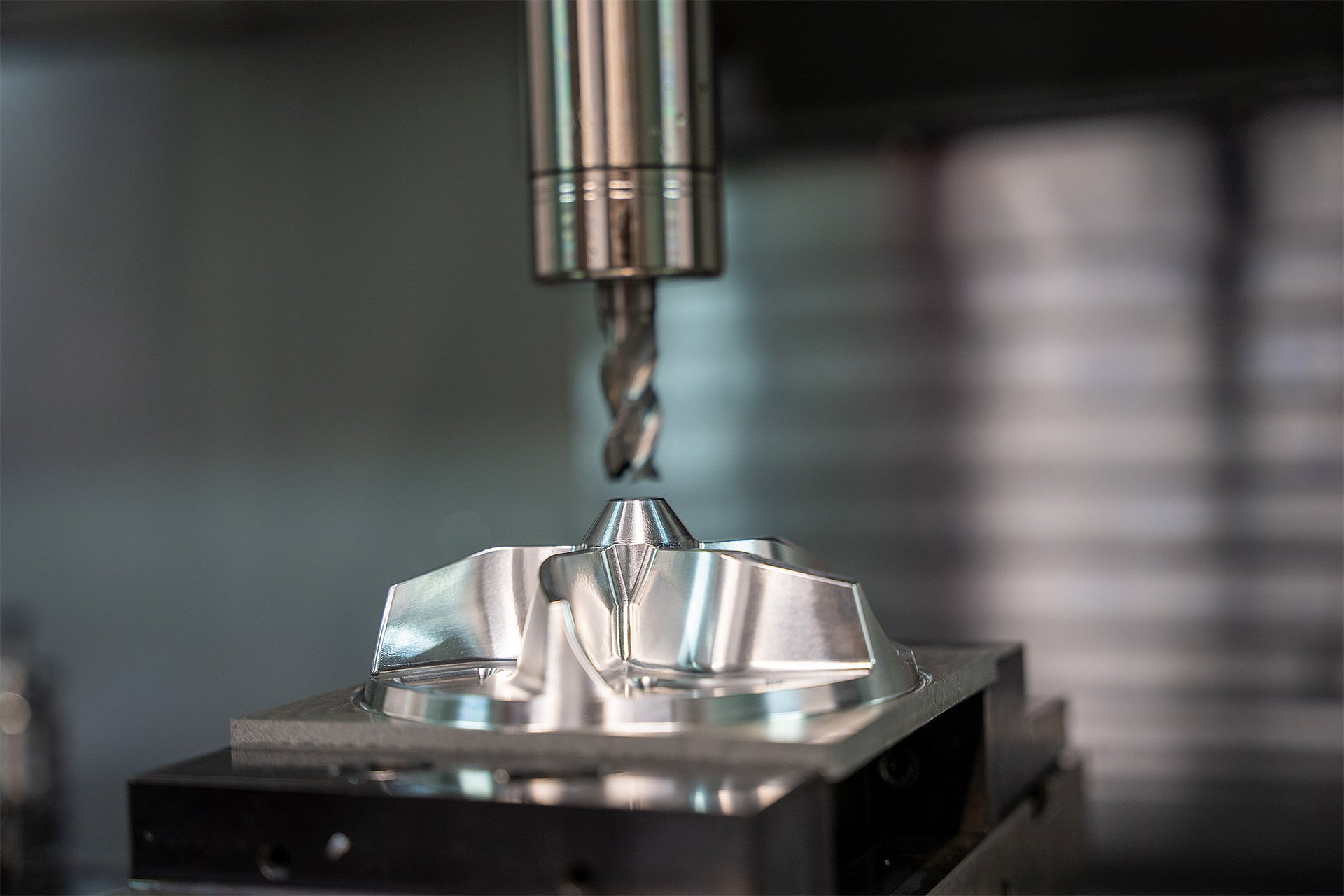

Prototype construction

Different prototypes are necessary depending on the requirements and project progress. At DMTpe, we explicitly evaluate which prototype and which prototyping process is best suited to your application. We manufacture prototypes using classic manual manufacturing processes or additive or generative processes. If other processes are better suited to your individual needs, we can draw on our network of partners . Just like DMTpe, our network of strong partners ensures the implementation of your prototypes using the latest technologies and guarantees you a fast time-to-market . We also assemble modules or fully functional complete devices, put them into operation and test the resulting prototypes according to the previously created test and verification plans. Interactive prototypes , e.g. for testing user interfaces and the usability of medical devices, are also part of our service portfolio.

Our competences

All common processes

Fast realization of prototypes with all common manufacturing and production technologies

Manufacturing and procurement

Production and procurement of individual parts, assemblies and complete devices from a single source

First series production

Industrial design, feasibility and functional prototypes as well as first series production