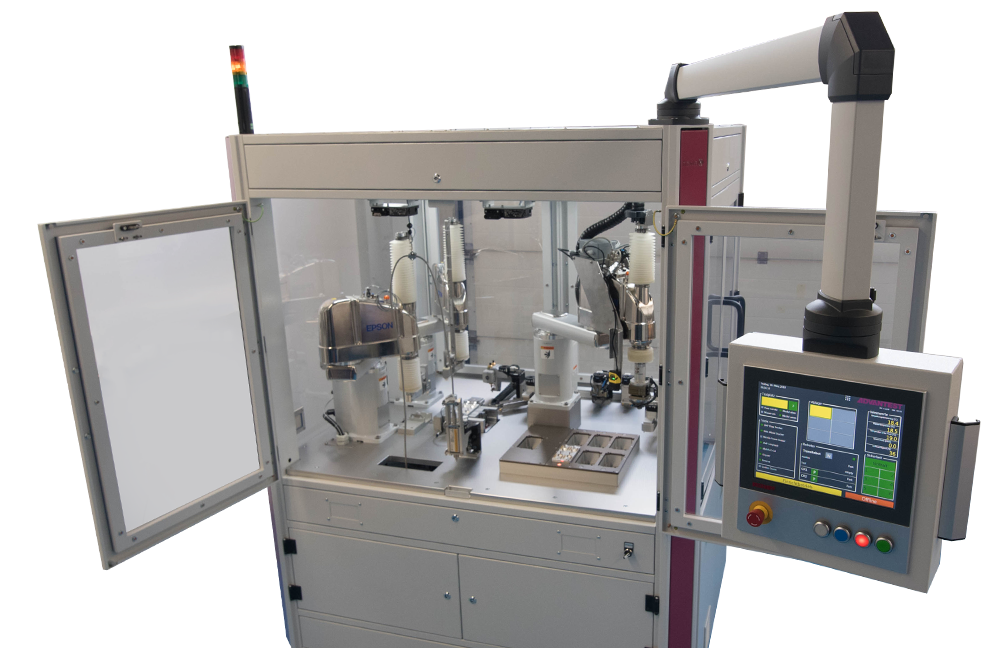

RFIM MEASURING CELL

Advantest GmbH

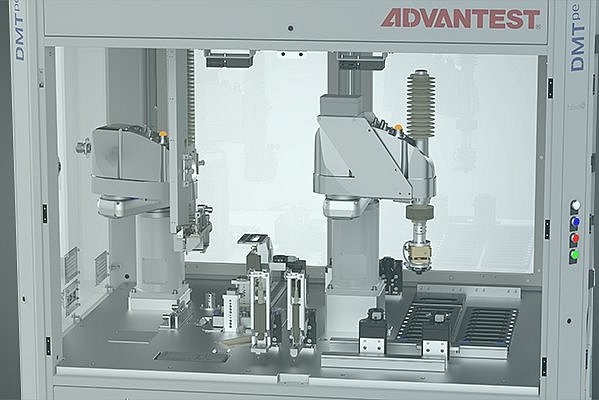

Fully automated characterization of RFIMs (Radio Frequency Interface Modules).

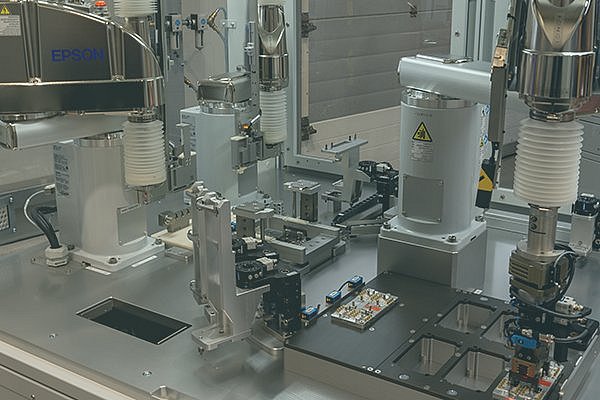

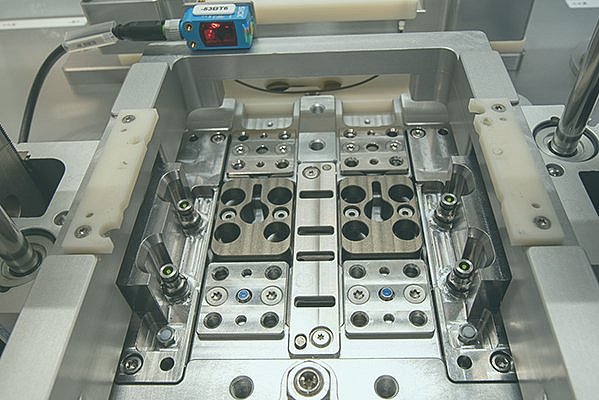

The fully automated measuring cell can be controlled via a measuring computer provided by the customer with defined commands and parameters. This allows the customer to design the measuring process flexibly. The robot can be loaded with up to 20 RFIM components in a magazine. A handling system (4-axis robot) removes the RFIMs from the magazine using a pneumatic gripper and places them in the test nest. There, the RFIMs are centered and contacted from below with RF connectors. At the same time, the cooling water supply is docked onto the RFIM. Another 4-axis robot approaches the contacts to be measured with signal frequencies in the gigahertz range on the top of the RFIM. Numerous actuators and sensors control and monitor the measuring process, the handling systems and the cooling water flow.

A PLC controls all processes and communicates with the customer's measuring computer. After characterization, the RFIM is returned to the magazine and the next component is inserted into the test nest. The RF measurement technology is very sensitive and must be positioned with high precision. The handling system uses various tools to automatically calibrate the entire measurement setup before the actual characterization of the RFIMs begins. The various calibration tools are mounted on the handling system using a pneumatic tool changing system.

Main features of the Advantest series:

- Fully automated systems for characterizing electronic modules

- Use of the systems in production lines

- Script control via a measuring computer provided by the customer

- Docking in the gigahertz range with wear monitoring of the connectors

- Monitoring of component positions during all handling steps

- Control and monitoring of the cooling water flow

- Tool changing system for holding and handling various calibration tools

- Integrated camera for scanning data matrix codes on the components and on the calibration tools

Development services of DMTpe

- Determination of system requirements in workshops with the customer

- Conception and creation of functional specifications

- Interface definition between measuring computer and machine control system

- Carrying out preliminary tests for the feasibility check

- Development of the mechanical assemblies and the overall system for automation

- Integration of the robots, pneumatics and sensors

- Electrical design

- PLC programming (Beckhoff) and programming of the robot controller (EPSON)

- HMI development

- Risk assessment and CE marking

- Mechanical assembly, switch cabinet construction and commissioning

- Checklists and functional tests

- Installation, commissioning and acceptance by the customer

"DMT Produktentwicklung GmbH successfully implemented a new calibration concept for us. The structured project management and competent technical implementation made it possible to create an innovative and reliable automation solution within the given time frame."